Welcome to Efficient NDT

Leading the way in Non-Destructive Testing Services – Ensuring Integrity, Safety and Reliability.

About Us

Efficient NDT Services (Pty) Ltd is a BBBEE Level 1 and 100% black women owned company. We are leaders in Non-Destructive Testing (NDT) services.

We provide comprehensive state of the art NDT solutions designed to ensure the safety, integrity and longevity of your critical assets. Our experienced team of certified professionals are committed to delivering unparalleled accuracy, efficiency and quality using the latest technology to meet the diverse needs of industries worldwide.

Our Mission

To deliver exceptional Non-Destructive Testing services that enhance the safety, reliability, and sustainability of our clients’ operations. We are dedicated to innovation, excellence and the continuous advancement of NDT technologies and methodologies.

Our Values

Integrity: We operate with the highest ethical standards and transparency.

Safety: We prioritize the safety of people, operations and the environment.

Quality: We are committed to delivering superior service and results.

Innovation: We continuously improve and innovate to meet the challenges of an evolving industry.

Services

Advanced NDT Methods

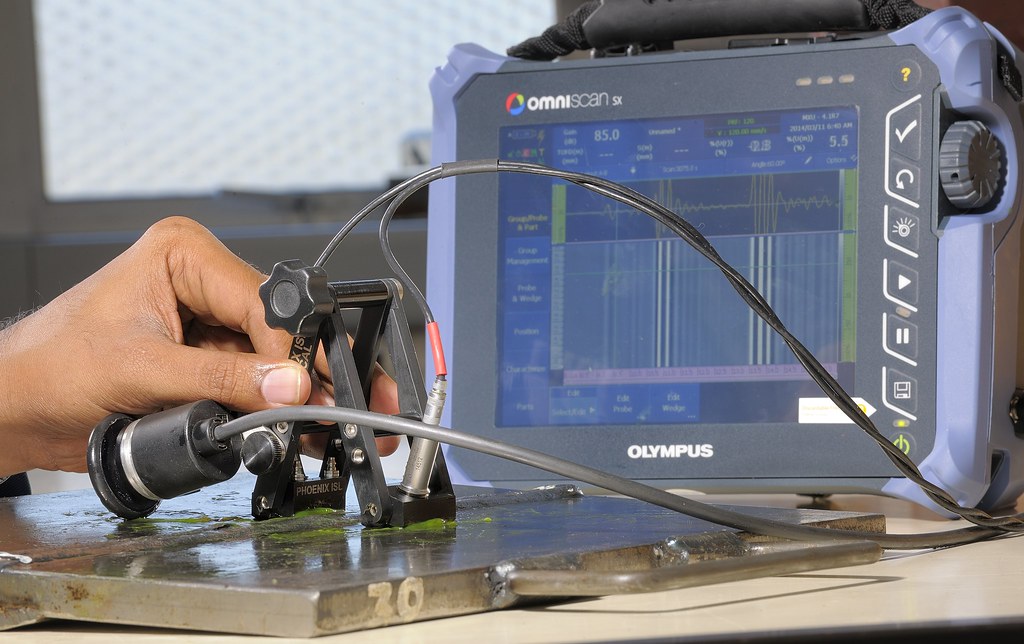

Phased Array Ultrasonic Testing (PAUT)

Precisely locates and characterizes cracks in materials, facilitating early detection and proactive maintenance to prevent catastrophic failures.

Time of Flight Diffraction (ToFD)

Technique that employs ultrasonic waves to detect and size defects within materials, able to accurately characterize the type, size, and orientation of flaws.

Ultrasonic Testing (UT)

High-frequency sound waves to detect internal and surface defects such as cracks, voids, inclusions and other discontinuities in materials like metals, composites, and plastics.

Eddy Current Testing (ECT)

Electromagnetic testing method to detect surface and sub-surface defects. Gauging the thickness of materials and identifying areas of thinning due to corrosion or wear without the need for direct access to both sides of the specimen.

Radiography Testing (RT)

Uses X-rays or gamma rays to view the internal structure of a component. Checks for corrosion, erosion, or damage inside complex structures and components, such as pipelines, pressure vessels and aircraft parts.

Replica Testing

Captures the surface features of a component or material, monitoring the microstructural changes in materials that occur over time due to factors like stress, temperature, and corrosion.

Conventional NDT Methods

Hardness Testing (HT)

Verifies the material grade and ensure that the correct material has been used for a specific application, also ensures that parts have been manufactured and treated correctly, meeting the specified hardness requirements.

Dye Penetrant Testing (PT)

Reveals surface-breaking defects in non-porous materials, finds surface cracks in components, even those too small to be seen with the naked eye.

Magnetic Particle Testing (MT)

Detects surface and near-surface discontinuities in ferromagnetic materials. Detects cracks, fatigue, and other flaws in critical components.

Positive Material Identification (MPI)

Verifies the chemical composition of metallic alloys, ensures that the material matches the specified chemical composition and thereby confirms its grade and specification.

Visual Testing (VT)

Direct visual assessment to detect surface defects and conditions. Ensuring that products meet quality standards and specifications from the initial stages of production through to final inspection.

Industries

Industrial & Construction

Mining

Oil & Gas

Power Generation

Petrochemical

Water

Contact

Location:

Johannesburg Branch

Block C, Stoneridge Office Park,

Greenstone Hill,

Johannesburg,

1906

Mpumalanga Branch

5 Dolerita Crescent,

Middelburg,

1050

Telephone:

011-201-2000

067 431 4989

Email:

Your message has been sent

Questions, comments or requests?

Feel free to reach out, we’d love to hear from you.